To extend your ribbon mic’s lifespan, handle it gently and avoid sudden movements or impacts that can damage the delicate ribbon inside. Store it in a climate-controlled, dust-free environment using a protective case, and keep humidity levels stable. Regularly inspect for dirt or damage, clean with soft tools, and avoid harsh chemicals. Proper connection and routine maintenance help prevent issues. With more tips, you’ll ensure your microphone stays in top shape longer.

Key Takeaways

- Handle the microphone gently, avoiding abrupt movements and shocks to prevent ribbon damage.

- Store in a dry, climate-controlled environment using protective cases to prevent corrosion and physical stress.

- Regularly inspect the ribbon and internal components for tears, dents, or dust buildup.

- Use windscreens and pop filters to reduce moisture exposure and protect delicate parts during use.

- Schedule professional maintenance and repairs when signs of damage or performance issues appear.

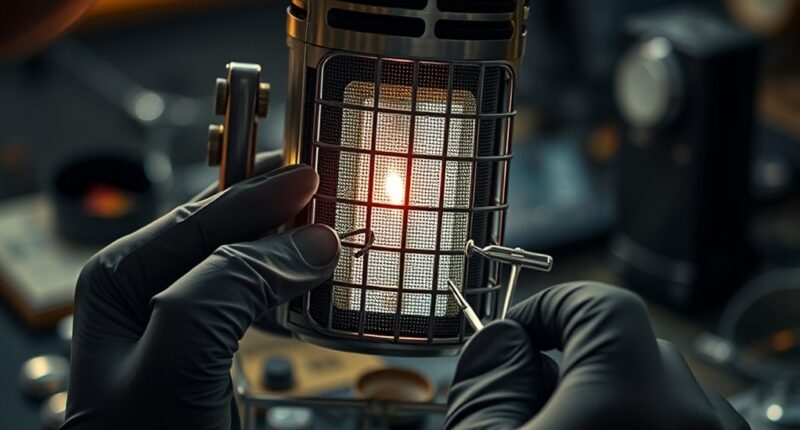

Understanding the Construction of Ribbon Microphones

Understanding how ribbon microphones are constructed is essential for proper maintenance and ideal performance. You should know that a ribbon microphone features a thin metallic ribbon, usually made of aluminum or similar metal, suspended within a magnetic field. When sound waves hit the ribbon, it vibrates, causing electrical signals to be generated through electromagnetic induction. The ribbon’s fragility means it can easily be damaged by sudden loud sounds or improper handling. The magnet assembly surrounds the ribbon, creating a consistent magnetic field that helps convert vibrations into electrical signals efficiently. Recognizing these core components helps you understand how delicate the ribbon is and the importance of preserving its integrity. Additionally, understanding the magnetic field involved in the design can help you appreciate the sensitive nature of the ribbon and the need for careful handling. Proper storage techniques are crucial for preventing damage and maintaining performance over time. This foundational knowledge is vital for maintaining your microphone’s performance and longevity over time, especially when considering proper storage and handling techniques.

Handling Your Ribbon Microphone With Care

Handling Your Ribbon Microphone With Care

To keep your ribbon microphone in top shape, handle it gently and avoid sudden movements. Always store it properly when you’re not using it, especially during long breaks. Taking these simple steps helps protect the delicate ribbon element and extends its lifespan. Additionally, being aware of environmental factors like humidity and temperature can prevent damage to the microphone’s components environmental considerations. Regular maintenance and careful handling are essential for preserving the microphone’s sound quality. Proper storage and avoiding exposure to extreme conditions can also minimize the risk of damage caused by moisture and temperature fluctuations.

Use Gentle Handling Techniques

Because ribbon microphones are delicate by nature, handling them with care is essential to prevent damage. Always lift and move the microphone gently, avoiding sudden jerks or drops. When connecting or disconnecting cables, do so smoothly to prevent stress on the internal components. Hold the microphone by its body or designated grip points, not by the grille or ribbon area. Be cautious when adjusting positioning, and avoid applying excessive pressure or force. Keep your movements slow and controlled, especially near sensitive parts. Use a soft cloth or brush to clean dust or debris gently, never using harsh tools or chemicals. Additionally, understanding the fundamentals of microphone design can help you better appreciate how to handle your equipment properly, minimizing risk and ensuring it maintains excellent performance over time. Being aware of the sensitivity of ribbon elements also emphasizes the importance of careful handling to prolong the life of your microphone. Proper storage in a protective case when not in use can further prevent damage and extend the lifespan of your ribbon microphone. Recognizing the materials used in ribbon elements can guide you in choosing appropriate cleaning and handling methods.

Avoid Sudden Movements

Why is it so important to avoid sudden movements when handling your ribbon microphone? Because quick or jerky motions can cause the delicate ribbon element to shift or tear. These ribbons are extremely fragile and sensitive to physical shocks. Even a slight jolt can damage the thin metal film inside, leading to reduced sound quality or complete failure. When you move the microphone, do so slowly and smoothly to prevent undue stress. Always handle it with steady hands, avoiding abrupt twists or drops. Remember, the more controlled your movements, the less risk there is of damaging the internal components. Protecting your ribbon mic’s integrity ensures it continues to deliver clear, professional sound for years to come. Handle it gently, and it’ll reward you with reliable performance.

Store Properly When Idle

When your ribbon microphone is not in use, storing it properly is essential to protect its delicate internal components. Keep it in a dry, cool place away from direct sunlight and extreme temperatures to prevent damage. Use a protective case or cover to shield it from dust, dirt, and accidental impacts. Avoid placing heavy objects on top of it, which could crush or deform the fragile ribbon element. If possible, store the microphone vertically to minimize stress on internal parts. Ensure that the storage area has stable humidity levels, as excessive moisture can corrode internal components. Proper storage not only preserves the microphone’s integrity but also extends its lifespan, ensuring consistent performance whenever you need it. Additionally, understanding the horsepower of electric dirt bikes can help you appreciate the importance of careful handling and maintenance of sensitive equipment. Proper handling and vintage microphone care are essential to maintain optimal audio quality and prevent costly repairs.

Proper Storage Techniques for Fragile Ribbons

To guarantee your fragile ribbon microphone stays in top condition, proper storage is essential. Store them in a dry, dust-free environment, ideally in a protective case or wrap them in anti-static material. Avoid extreme temperatures and humidity, which can damage the ribbon. Choose a location away from direct sunlight and magnetic sources. Use the table below as a quick reference for ideal storage conditions:

| Storage Environment | Temperature Range | Humidity Level |

|---|---|---|

| Climate-controlled room | 60-70°F | 40-50% RH |

| Protective case | Stable, cool | Low moisture |

| Shelving unit | Away from heat | Keep dry |

| Storage drawer | Acid-free lining | Maintain humidity |

| Transport case | Shock absorption | Secure placement |

Proper storage preserves your ribbons’ delicate structure and ensures longevity. Additionally, remote hackathons can be a useful resource for accessing diverse expertise and ideas for audio equipment development and innovation. Maintaining a consistent storage environment can also help prevent corrosion and mechanical issues over time.

Cleaning and Maintaining Your Ribbon Microphone

Proper cleaning and maintenance are essential for keeping your ribbon microphone performing at its best. Regular care prevents dust buildup and protects the delicate ribbon from damage. To do this effectively:

- Gently use a soft brush or microfiber cloth to remove dust from the grille and body.

- Use a compressed air can to blow away particles from hard-to-reach areas.

- Avoid using liquids or solvents directly on the microphone; instead, lightly dampen your cloth if necessary.

- Handle the microphone carefully during cleaning to prevent accidental damage to the ribbon or internal components.

Avoiding Harmful Environmental Conditions

To keep your ribbon mic in top shape, you need to control the environment around it. Make sure humidity levels stay steady, and avoid sudden temperature changes that can cause damage. Protect your microphone from corrosive elements like dust and chemicals to prevent deterioration. Additionally, avoiding exposure to harmful environmental conditions is crucial for maintaining the longevity of fragile ribbons. Proper room ventilation and avoiding exposure to moisture can further help preserve the delicate components of your microphone. Being aware of emotional support can also help you manage stress related to equipment maintenance and troubleshooting.

Control Humidity Levels

Maintaining the right humidity levels is essential for keeping your ribbon microphone in ideal condition. Excess humidity can cause corrosion and warping of delicate parts, while low humidity increases static and causes materials to become brittle. To protect your mic, consider these steps:

- Keep the environment between 40-50% humidity to prevent moisture damage.

- Use a dehumidifier or humidifier in your recording space to maintain consistent levels.

- Store your microphone in a sealed, climate-controlled case when not in use.

- Regularly monitor humidity with a hygrometer to catch fluctuations before they cause harm.

Minimize Temperature Fluctuations

Temperature fluctuations can considerably harm your ribbon microphone by causing materials to expand and contract, which may lead to misalignment or damage over time. To prevent this, keep your mic in a stable environment with consistent temperatures, ideally between 65°F and 75°F (18°C – 24°C). Avoid placing it near heaters, air conditioners, or windows with direct sunlight, as these sources can create rapid temperature shifts. When moving the microphone between different locations, allow it to acclimate for a few hours before use. Use climate-controlled rooms whenever possible, and store the mic in a dedicated case with insulation to shield it from sudden temperature changes. Consistent conditions will help preserve the integrity of the ribbon and ensure peak performance over the long term.

Protect From Corrosive Elements

Are corrosive elements threatening your ribbon microphone? Exposure to moisture, dust, or chemicals can quickly damage the delicate ribbon. Protecting your mic from these hazards is vital for longevity.

Here’s what you can do:

- Keep it in a controlled environment—avoid humid or salty spaces.

- Use protective covers when not in use to shield from dust and pollutants.

- Install dehumidifiers in your recording area to prevent moisture buildup.

- Regularly inspect and clean your microphone to catch corrosion early.

Don’t let harmful elements ruin your investment. Taking these simple steps can save you costly repairs and preserve the pristine sound quality your ribbon mic provides. Stay vigilant, and your mic will reward you with years of reliable performance.

Using Appropriate Accessories and Windscreens

Have you considered how the right accessories and windscreens can protect your ribbon microphone and improve its performance? Using a dedicated windscreen reduces the risk of breath and plosive blasts that could damage the delicate ribbon. A pop filter helps minimize plosives and prevents moisture from reaching the mic’s element. Additionally, choose accessories made from materials that won’t cause static or damage, like foam or mesh specifically designed for ribbon mics. Properly fitted windscreens also reduce wind noise and handling noise, ensuring cleaner recordings. Keep in mind that not all windscreens are suitable for every mic, so select ones recommended by the manufacturer. Incorporating these accessories is a simple, effective way to extend your microphone’s lifespan and maintain ideal sound quality.

Safe Connection and Disconnection Procedures

To guarantee your ribbon microphone remains in ideal condition, always follow proper connection and disconnection procedures. Handling your mic carefully prevents accidental damage and preserves its delicate ribbon.

Here are four essential steps to ensure safety:

- Power down your equipment before plugging or unplugging to avoid static or electrical surges.

- Hold the connector firmly by its plug, not the cable, to prevent stress on the fragile ribbon.

- Connect and disconnect gently, avoiding force that could bend or break internal components.

- Keep your hands clean and dry to prevent corrosion or static buildup, which can harm sensitive parts.

Regular Inspection and Troubleshooting

Regular inspections help catch issues early and keep your ribbon mic sounding its best. You should routinely check for visual signs of damage, like dents or loose parts, and listen for audio anomalies such as distortion or dropouts. When problems arise, troubleshooting common issues quickly ensures your mic stays reliable and performs ideally.

Visual Inspection Techniques

Performing visual inspections is a crucial step in maintaining your ribbon microphone’s performance and longevity. Regularly examining your mic helps catch issues early before they cause damage. Focus on these key areas:

- Check the ribbon for tears, creases, or dents—any damage can weaken sound quality and risk further harm.

- Inspect the diaphragm’s surface for dust, dirt, or corrosion that could affect it’s responsiveness.

- Look for loose or damaged wiring connections that might cause intermittent sound or failure.

- Examine the enclosure and grille for dents, cracks, or corrosion that could compromise shielding or structural integrity.

Detecting Audio Anomalies

Have you ever noticed a sudden drop in sound quality or irregularities in your microphone’s output? If so, it’s time to pay close attention. Listen carefully to the audio signals during recordings or live use. Unusual hums, crackles, or inconsistent volume levels often indicate issues like damage or debris on the ribbon. Use headphones to isolate the problem more effectively. Check for distortions, rattles, or loss of high frequencies, which can signal ribbon misalignment or deterioration. Keep an ear out for sudden drops in clarity or sudden noise bursts. Regularly monitoring your microphone’s output helps catch problems early, preventing further damage. Trust your ears; they’re your best tool for detecting audio anomalies that may suggest your ribbon needs professional inspection or repair.

Troubleshooting Common Issues

Wondering how to keep your ribbon microphone in top shape? Regular inspection and troubleshooting are key. First, listen carefully for unusual sounds or dropouts—these often signal issues. Second, check the ribbon for tears or dents; even minor damage can distort sound. Third, examine the connections and cables for looseness or corrosion that might cause interference. Fourth, verify the magnet assembly and baffle for dust or debris that could impair performance. Address issues promptly by cleaning gently and replacing damaged parts. Don’t ignore subtle changes in sound quality—they’re often clues to underlying problems. Staying vigilant with routine checks ensures your microphone stays delicate but reliable, giving you clear, professional recordings every time.

When and How to Seek Professional Repairs

While some minor issues with your ribbon microphone can be addressed through basic troubleshooting, it’s important to recognize when professional repairs are necessary. If you notice persistent distortion, unusual noises, or a complete loss of sound, don’t attempt DIY fixes. Instead, seek expert help promptly to prevent further damage. The table below highlights common signs indicating professional repair is needed:

| Symptom | Possible Cause | Urgency Level |

|---|---|---|

| No sound or very low output | Ribbon or transformer damage | Immediate |

| Unusual buzzing or crackling | Loose connections or damage | High |

| Reduced frequency response | Ribbon misalignment | Moderate |

| Intermittent issues | Internal component failure | Moderate |

| Visible physical damage | Bent or torn ribbon | Immediate |

Knowing when to consult professionals helps preserve your mic’s fragile ribbon.

Tips for Extending the Overall Lifespan of Your Ribbon Microphone

To maximize the lifespan of your ribbon microphone, it’s essential to handle it carefully and stick to proper maintenance practices. Protecting the delicate ribbon is your top priority. Here are four tips to help you extend its life:

- Store it in a protective case when not in use to prevent dust and accidental damage.

- Keep it in a controlled environment, avoiding extreme temperatures and humidity that can weaken components.

- Handle it gently during setup and transport, avoiding sudden shocks or drops.

- Regularly inspect and clean the grille and exterior to prevent dust buildup that can compromise sound quality.

Following these steps ensures your microphone remains reliable and performs at its best for years to come.

Frequently Asked Questions

How Can I Identify Early Signs of Ribbon Deterioration?

You want to spot early signs of ribbon deterioration, so listen carefully to your microphone’s sound. If you notice a decrease in volume, a dull or muffled tone, or unusual distortion, these might be signs the ribbon is weakening. Also, check for physical damage or creases on the ribbon itself. Regularly inspecting and handling your mic gently helps catch issues early, ensuring you prolong its lifespan and maintain peak sound quality.

Are There Specific Cleaning Products Safe for Ribbon Microphones?

They say a clean machine runs smoothly, and that applies to ribbon mics too. Use a soft, dry brush or a can of compressed air to gently remove dust—avoid harsh chemicals or liquids that can damage the delicate ribbon. If you must use cleaning products, choose alcohol-based solutions with a low concentration, and always test a small area first. Regular cleaning helps preserve your mic’s longevity and sound quality.

What’s the Recommended Lifespan for a Typical Ribbon Element?

The typical lifespan of a ribbon element varies, but with proper care, it can last 10 to 20 years or more. You should handle it gently, avoid extreme humidity or temperature, and keep it clean. Regular maintenance, like careful cleaning and safe storage, helps extend its life. Remember, a well-maintained ribbon mic performs better and lasts longer, saving you money and ensuring consistent sound quality over time.

Can Ambient Humidity Affect Ribbon Microphone Longevity?

Ever wonder if ambient humidity is secretly plotting against your ribbon mic? Turns out, it does! High humidity can cause the delicate ribbon to corrode or become misshapen over time. You might think a humid day is harmless, but it actually accelerates wear and shortens your mic’s lifespan. To protect your gear, keep it in a controlled environment, away from moisture, and consider using desiccants or a dehumidifier.

How Often Should Professional Maintenance Be Performed?

You should perform professional maintenance on your ribbon microphone at least once a year, especially if you use it frequently or in challenging environments. Regular check-ups help identify issues early, like ribbon wear or dust buildup, which can damage the delicate components. If you notice a drop in sound quality or unusual noise, get it inspected sooner. Proper maintenance guarantees your mic stays in the best condition and extends its lifespan.

Conclusion

By following these maintenance tips, you can substantially extend the life of your fragile ribbon microphone. While it might seem delicate, proper care and handling make a real difference. Some may worry that routine upkeep isn’t worth the effort, but investing a little time now prevents costly repairs later. With consistent upkeep, your ribbon mic will deliver exceptional sound quality for years to come, proving that careful maintenance truly preserves both your equipment and your investment.